Interview with the hydrogen expert Andreas Dobsch from the Schuck Group

H2 - HYDROGEN AS A CHALLENGE AND AN OPPORTUNITY

With the announcement of the hydrogen strategy in June 2020, the German Federal Government ushered in a new era in the use of alternative energy sources. The use of so-called green hydrogen as a game changer in the energy industry plays the central role in this.

For us as an established system manufacturer for all aspects of energy supply and as an innovative pioneer in the industry, it is a matter of course to take the lead here.

The Schuck Group has already got in the mood for this mega trend and has started developing its products further and new at an early stage.

We spoke to Andreas Dobsch, Head of Construction & Development, Distribution.

Why is the Schuck Group concerned with the subject of hydrogen?

As already described in the last interview with our product manager Robert Barthle (Link), the future use of hydrogen as an energy carrier will significantly change the entire energy industry as well as parts of heavy industry (including steel producers) and the transport and mobility sector.

“For the long-term success of the energy transition and for climate protection, we need alternatives to fossil fuels. Hydrogen will play a key role as a versatile energy carrier. " (bmwi.de)

As a result, our business partners are faced with the challenge of transporting gases that will change in the future (hydrogen and mixed gases from natural gas and hydrogen) in existing and new distribution and transport networks. The goal of Schuck Group is to provide our partners with a perfect solution or a perfect system that meets both today's and the requirements of the future. With our products "for the network of tomorrow" we offer our customers systems with which they are equipped for the future.

What are the special challenges with the medium hydrogen for components in the gas network?

Hydrogen, as the smallest chemical element in the periodic table, has enormous potential to revolutionize the energy industry, but also has certain properties that have to be taken into account when transporting the medium and manufacturing corresponding products.

For example, the property of hydrogen diffusing into materials can lead to embrittlement and failure of the materials ("hydrogen cracking"), but also the property of permeating through materials to penetration, e.g. of elastomers, there is the additional challenge that there are only a few current national and international standards.

How did the Schuck Group react to these challenges?

As an innovative provider of distribution and transport systems for, among other things, gaseous media, we saw it as our duty to actively take up and solve this challenges As part of the “Schuck Hydrogen Design” project, we identified priorities, developed solutions and implemented them in our portfolio. The result is a specially developed requirement profile “Schuck Guideline for Hydrogen” as well as an H2ready product portfolio based on this guideline.

What were the priorities of the Schuck Hydrogen Design project?

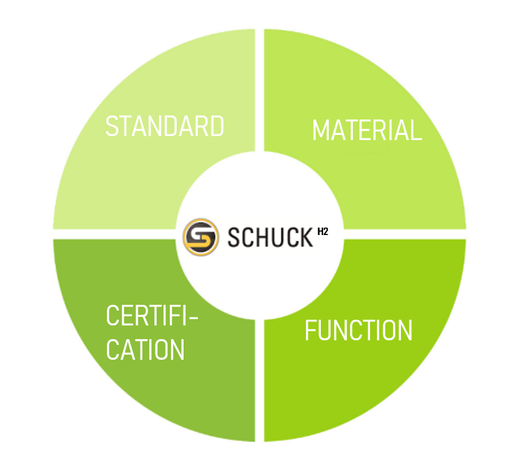

Basically, the project was based on several topic clusters, which were subdivided into the four main areas of standard, material and functional testing and product certification.

1. STANDARD

The Standard Cluster included extensive research on national and international regulations and research documentation, participation in research and pilot projects in existing customer projects as well as activities with research and test laboratories and interdisciplinary exchange with companies from outside the industry (including ESA and NASA). As a result of this, we developed the Schuck Guideline for Hydrogen, which contains the current state of the art as well as knowledge from the aforementioned sources. With this document we are able to specify and manufacture products and provide them to our partners.

As part of several project groups of the DVGW, ÖVGW, figawa and other bodies, we actively share our findings with customers, operators and project partners with the aim of creating a standardized and high-quality product range for the transport and distribution of hydrogen.

2. MATERIAL

Under the focus on materials, both existing materials and newly used materials were verified with regard to their suitability based on the Schuck Guideline for Hydrogen. As part of this, the chemical composition and structure of steels and elastomers were examined and mechanical tests were carried out. Since vibrating, moving elements are particularly prone to H2-induced embrittlement, a highlight is a long-term load test of springs under a 100 bar hydrogen atmosphere, in which 80,000 cycles were carried out under full load without the springs showing any loss of function.

3. FUNCTION

A very important focus was placed on the functional test of all components, particularly with regard to a possible capital housing failure, but also with regard to the emission of the medium into the atmosphere. Together with our project partner, the DBI GTI - Freiberg, tests were carried out with various operating parameters (temperature, pressure, switching states, continuous alternating stress) with the test media hydrogen and, in addition, with helium. The tests of our pipeline valve "G-Hahn" were particularly outstanding due to the large volumes, nominal widths and test pressures. Fittings were pressurized with hydrogen up to a test pressure of 210 bar.

4. CERTIFICATION

In order to ensure the h2ready quality in the long term, with the focus on attestation, the test procedure was standardized and verified together with the DBI-GTI Freiberg and TÜVSaar, but a continuous production-accompanying method was also developed.

All topics of the project have already been successfully completed for a large part of the portfolio with the aim of providing high-quality, absolutely safe and yet economical products to our partners. You can find information on this in our new product application category of renewable energy sources.

There are already a large number of products that have been approved for use with hydrogen, although there are no generally applicable regulations. How do you guarantee the quality and safety of the components without the modified regulations?

We aim to provide our business partners with products for tomorrow's network today. We can only guarantee this if we act actively today and don't wait for rule-makers and legislators.

Of course, the focus is on security and the highest quality standards. We guarantee an absolutely safe product through the test procedures developed both in component testing and constant factory control, through continuous monitoring of in-house and external acceptance tests, as well as through our claim to deliver high-quality, innovative products.

Where and how does Franz Schuck GmbH participate in projects?

Our aim is to build up knowledge, to share knowledge and to further develop our knowledge. It is therefore very important to us to participate in networks as well as specific projects. We are already in a large number of project groups, including the DVGW, ÖVGW, figawa, with the aim of establishing the regulatory landscape with regard to the new requirements, but also advising customers and their project partners on the implementation of specific projects, e.g. real laboratories.

Since the transformation of the gas network will only succeed if a large part of the current infrastructure can continue to be used, we also advise on the further use of components already in the natural gas network for possible use in future hydrogen networks.

How can existing products be assessed even though they have not been manufactured in accordance with the latest findings and requirement profiles?

This is an exciting question that we and our project partners have been wondering about very often! In the future, we will offer an evaluation in order to assist our partners with possible conversion projects.

Again, based on the Schuck Guideline for Hydrogen, we developed an evaluation scheme to analyse existing fittings with regard to their suitability for materials and functionality.

What were the outstanding milestones in the Schuck Hydrogen Design project?

The first release of our HSP gas house launch in 2020 will be remembered. It made the entire project team incredibly proud to be the first manufacturer of such systems to hold the H2ready brand in their hands and to present it to our partners. This milestone was the basis for everything else. The established network, the mechanisms and procedures as well as the know-how regarding the evaluation procedures of materials made further approvals much easier.

The release of the large valves / pipeline valves (ball valve type G) will always be remembered as a successful, major milestone. Applying a test pressure of 210 bar to a valve in such a volume requires, on the one hand, a high level of safety and confidence in the design of the product, but also a smoothly functioning project team (DBI-GTI, SGS-TÜVSaar, SCHUCK).

What's next?

It is already clear today that more milestones will follow. Renewable media will make a massive contribution to the energy mix in the future. It is therefore important that the development of the industry does not stand still.

We will and have already examined other renewable energy sources and the application components derived from them and will derive further, innovative products from them.

The entire Schuck Group team is proud to contribute to making the energy transition a successful model. We are happy to support you with your challenges, work on ideas and develop solutions together.